Shanghai City, China, 24th Oct 2025 – Pullner, a global provider of OEM and ODM filtration solutions, has announced a significant enhancement of its production capacity to address the rising international demand for high-performance industrial filters. This expansion marks a major step forward in strengthening the company’s ability to supply advanced filtration technologies to a wide range of industries, including microelectronics, petrochemical, power generation, pharmaceuticals, food and beverage, desalination, and automotive manufacturing.

The production enhancement involves the installation of automated equipment, the optimization of process flow, and the implementation of new quality management technologies. These measures are designed to support consistent manufacturing precision, faster delivery cycles, and improved scalability in response to the growing international demand for high-performance filter cartridges and housings.

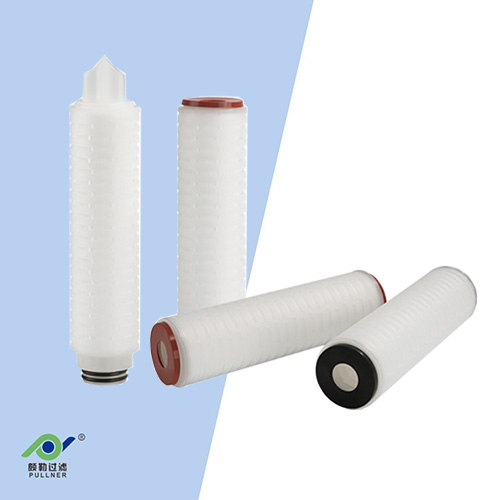

Filter cartridges produced by Pullner—such as high-flow, pleated, string wound, membrane, and stainless-steel types—play a crucial role in maintaining product purity and process integrity in industrial systems. As global industries place increasing emphasis on operational reliability and environmental compliance, the demand for high-efficiency filtration solutions has continued to expand. Pullner’s production growth initiative directly addresses this need through greater manufacturing output and continued adherence to global quality standards.

Lucy, Sales Manager at Pullner, commented, “This expansion reflects a deliberate commitment to industrial advancement and supply stability. The initiative ensures that clients in critical sectors have continuous access to filtration products engineered to perform under complex operational conditions, where consistency and precision are essential.”

The project is supported by Pullner’s ongoing research and development efforts, which focus on the improvement of filter media, the durability of structural components, and the optimization of fluid dynamics within cartridge design. Emphasis has been placed on extending filter lifespan, enhancing flow capacity, and reducing overall maintenance costs for end users. These advancements are guided by data-driven testing and rigorous material analysis to ensure compliance with industry benchmarks.

Environmental sustainability remains a key aspect of Pullner’s operations. The company is implementing energy-efficient production systems and waste reduction programs across its manufacturing facilities. The introduction of advanced recycling processes and resource-efficient materials forms part of a broader initiative to align the company’s operations with contemporary environmental standards.

The upgraded manufacturing site, located in the Jebel Ali Free Zone in Dubai, provides logistical advantages that facilitate faster regional and international distribution. Proximity to major trade routes allows Pullner to optimize export operations, supporting timely supply to clients throughout Asia, the Middle East, Africa, and Europe. The expansion also strengthens the company’s ability to maintain stable production schedules amid fluctuating market conditions.

Pullner’s enhanced production infrastructure reinforces its position as a trusted partner in the filtration industry, offering flexible OEM and ODM capabilities that accommodate both standard and customized specifications. The company’s engineers collaborate with industrial clients to ensure compatibility between filtration products and diverse system requirements, ensuring precision in application and reliability in performance.

Lucy added, “Future objectives will concentrate on the integration of intelligent manufacturing and digital monitoring systems. Continued investment in innovation and material science will ensure that Pullner remains a forward-looking contributor to industrial filtration technology, capable of meeting emerging global demands with efficiency and technical integrity.”

The company’s leadership views this expansion as a foundation for long-term operational resilience. By increasing production capacity and adopting modern process controls, Pullner aims to maintain consistent output while meeting international standards for safety, quality, and environmental stewardship.

Pullner’s ongoing initiatives reflect a commitment to precision manufacturing, continuous improvement, and sustainable development within the filtration sector. The company anticipates that the enhanced production capability will serve as a critical enabler of future growth and collaboration with industrial partners worldwide.

For more information, contact Pullner, an industrial filters manufacturer with an office located at 8th Building, No.1132 Maoting Rd., Chedun Town, Songjiang District, Shanghai City, 201611, China, by phone at +971 58 112 9568 or via email at sales@pullner.com.

Media Contact

Organization: Pullner

Contact Person: Lucy

Website: https://www.pullnerfilter.com/

Email:

sales@pullner.com

Contact Number: +862157718597

Address:8th Building, No.1132 Maoting Rd, Chedun Town, Songjiang District, 201611

City: Shanghai City

Country:China

Release id:35972

The post Pullner Enhances Production Capacity to Meet Global Demand for Industrial Filters appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Just Examiner journalist was involved in the writing and production of this article.